Microthrix parvicella

Identification

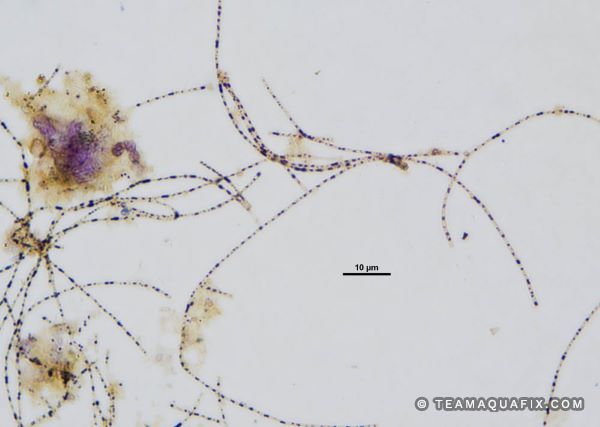

- Tangled spaghetti-like appearance

- Cells not clearly visible

- Stains strongly Gram positive

- Contains Neisser postive granules

Why Do I Have It?

- Present in systems with high incoming fats, oils, and greases (FOG)

- Temperature in system is below 18°C (65°F)

Effects on Wastewater Systems

Microthrix parvicella frequently causes or contributes to foaming and bulking in wastewater systems. While M. parvicella is known for forming a thick layer of dark brown scum up to around 6 inches, it can lead to foaming of a variety of colors and consistencies.

Treatment

If a plant experiences Microthrix parvicella, physical removal of grease before it enters the process is best. For biological correction, Aquafix recommends treating M. parvicella by metering in Qwik-Zyme L upstream. Qwik-Zyme L is designed to degrade undigestible grease compounds into short-chain fatty acids, a form consumable by the floc-forming bacteria. In conjunction, we recommend Foam Buster. Foam Buster provides nutrients that allow floc-forming bacteria to uptake short-chain fatty acids more efficiently, allowing the bacteria to outcompete M. parvicella.

Under the Microscope and in Your Plant

Microthrix parvicella is a narrow, tangled filamentous bacterium with an approximate diameter of 0.8 µm and ranges from 200-400 µm in length. This filament can cause bulking and foaming to occur. Microthrix parvicella prefers conditions with high incoming fats, oils, and greases (FOG), as well as temperatures below 18°C (65°F). This filament can be definitively identified when Neisser stained and viewed under 1000x magnification. M. parvicella almost always has Neisser positive granules. It also has no attached growth or sheath and its cells are not clearly visible with light microscopy. This filament stains strongly Gram positive. This filament can occasionally be confused with Nostocoida limicola as both filaments can have a similar size, tangled appearance, and stain Gram positive. The appearance of M. parvicella changes under anaerobic conditions; the filament will be shorter, have an easily visible cell shape, and will not stain as heavily Gram positive. M. parvicella can survive up to a month in an anaerobic digester and contribute to anaerobic foaming. However, this filament cannot grow within an anaerobic digester.

M. parvicella can grow within floc, preventing proper floc formation from occurring. Foaming, bulking, and scum formation can occur when M. parvicella forms a tangled mat-like structure and floats due to its low-density fatty cell walls. This filament typically creates a thin, dark-colored foam; however, foam color and consistency are not a definitive way to identify the cause of foaming. Using foam color or consistency can lead to an incorrect diagnosis which can lead to failed treatments.

Unique Experience in the Field

A municipal wastewater plant was experiencing M. parvicella foaming but was unsure how as they do not get grease buildups within their upstream lift station. This plant does, however, get high levels of incoming surfactants and infiltration and inflow (I&I). It is possible that these surfactants emulsified the grease, removing the grease out of their lift station. Incoming surfactants may have been acting as a source of fat, or emulsified fats were entering the process to contribute to the growth of M. parvicella. To treat this filament Aquafix recommended the use of SmartBOD and Qwik-Zyme L to break down emulsified grease and allow for floc forming bacteria to compete more effectively with Microthrix parvicella.

References

Jenkins, D., Richard, M.G., & Daigger, G.T. (2004). Manual on the causes and control of activated sludge bulking,

foaming, and other solids separation problems (3rd ed). CRC Press LLC.