Anaerobic Digester Upset & Troubleshooting

Anaerobic digesters of all forms—municipal, industrial, waste-to-energy, agricultural—are popping up all over the world to harness wastewater for its valuable methane energy. In 2014 our chemist, Dan, consolidated and made sense of the information below, which years of our ongoing research in anaerobic digester issues. Through our research and trials, we have developed these core products to improve methane production, control foaming, and raise the pH in anaerobic environments:

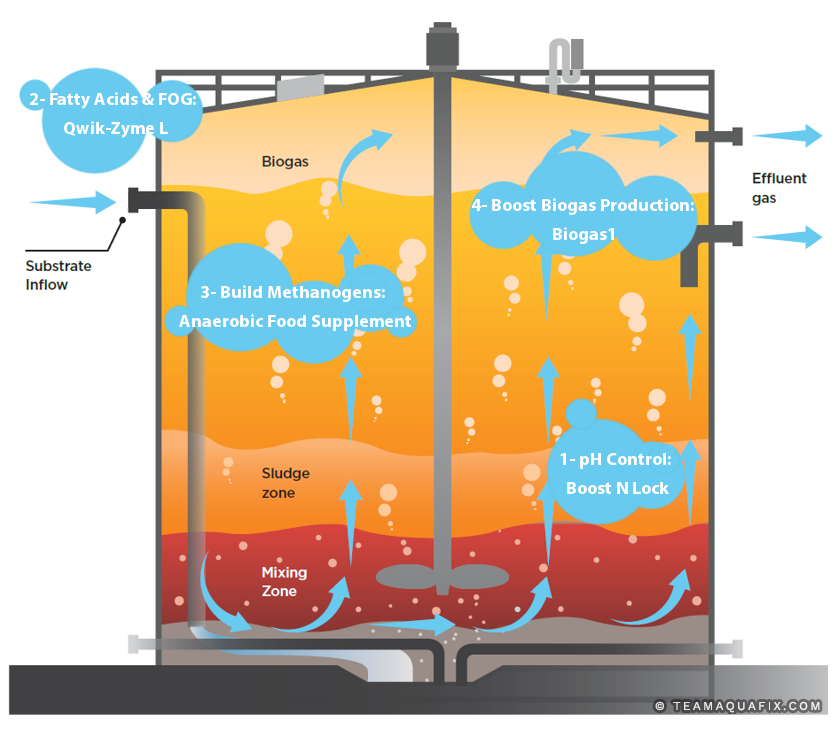

- BioGas1 – A bioavailable source of key trace elements

- Anaerobic Food Supplement – A food source that builds methane-forming bacteria Populations

- Qwik-Zyme L – A biochemical catalyst to quickly breaks down fatty acids

- Boost N Lock – Safe and effective pH increase

We hope this article helps you. Aquafix is always looking for new partners in all areas, within the United States and outside of it, and we would welcome hearing from you. For additional technical discussion call us at 888-757-9577 or email technicalservice@teamaquafix.com. You will find our service helpful and friendly.

I. Recommended Operating Conditions

Temperature

- Mesophilic digesters temperatures should be maintained between 32-35°C (90-95°F).

- Temperature changes per day should be no more than 2-3°C (4-6°F) per day. A .5°C (1°F) change per day is ideal.

Most anaerobic digesters are mesophilic. This is because mesophilic temperature conditions are easier to maintain then thermophilic. Mesophilic digesters require a consistent temperature between 32-35°C (90-95°F) as opposed to 50-60°C (122-140°F) for thermophilic conditions (Gerardi 127). Falling outside this range of conditions can cause methane production to slow down which leads to a volatile acid buildup. Generally the high end of the temperature range is preferable because it allows for faster biocatalyst function, sludge reduction, and methane production. An important consideration is to not allow any rapid change in temperature to occur. Mesophilic digesters should never change temperature more than 2-3°C (4-6°F) per day (Gerardi 91). In fact, some sources recommended only allowing a change of .5°C (1°F) per day. It is important that if the temperature of a digester drops, that its temperature is not recovered too quickly. This can very easily lead to an upset digester.

Thermophilic Digesters

Thermophilic digesters are typically operated between 50-60° Celsius (120-140° Fahrenheit). This higher operating temperature leads to a variety of advantages and disadvantages to the more commonly operated mesophilic digesters. The main reason thermophilic digesters are not more commonly used is due to the significantly higher energy input required to maintain a temperature above 50° C, but there are many other factors which could encourage or discourage the use of thermophilic digestion. The most important thing to know is that everything happens faster with thermophilic digesters, which includes upsets.

PROS

- Much faster COD reduction with consistent loading

- Improved solid/liquid separation

- Somewhat increased methane production

- Improved destruction of pathogens at high temperatures allows the production of class A bio-solids

- A higher rate of destruction of filamentous bacteria reduces the likelihood of filamentous foaming

- Faster decomposition of solids

CONS

- Much higher energy input

- Decreased bacterial diversity at higher temperatures leads to less digester stability

- Upsets occur much faster due to faster bacteria metabolism

- Poor degradation of long chain fatty acids at this temperature due to limited diversity of bacteria

- Poorer quality supernatant is produced

- Tends to generate more propionic acid which can cause problems for methane generation

- Less stable process requires more consistent organic loading to operate consistently

Because of these pros and cons, thermophilic digesters tend to be less suited for domestic wastewater treatment, but can be very effective for COD reduction in consistent industrial waste. Thermophilic digesters require even more stable temperature and loading conditions than mesophilic digesters. Class A bio-solids production also could create a financial incentive which could compensate for high energy input. The increase in methane production can also reduce electrical costs of operating a thermophilic digester somewhat. In plants with inconsistent loading, benefits of thermophilic systems can be outweighed by an increased likelihood of upsets.

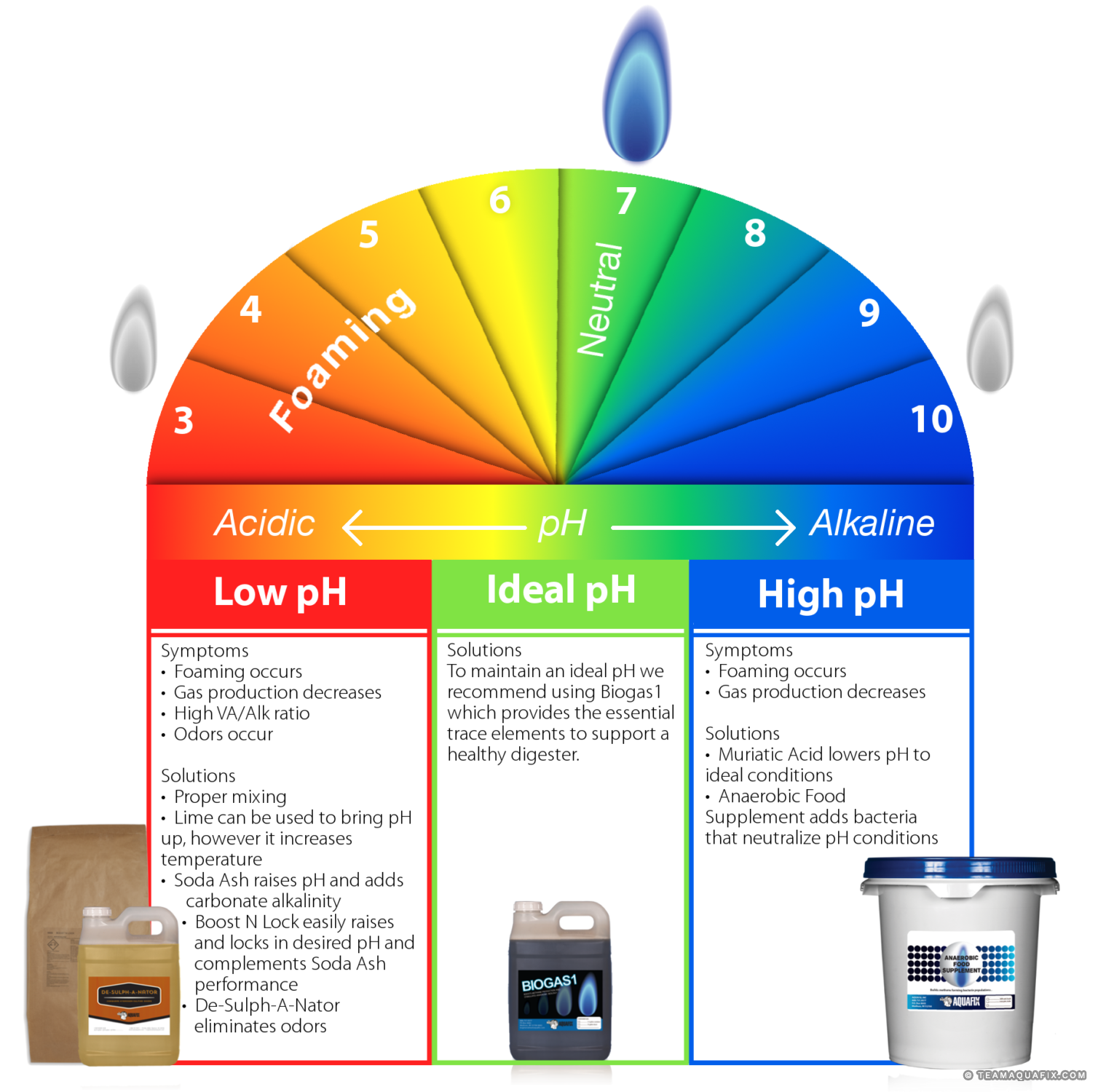

pH and Alkalinity:

- VA/Alk ratio should be below 0.34 (0.1 is better) to maintain a stable pH

- VA/Alk ratio can be calculated by dividing the total volatile acids in a solution by the total alkalinity

- Drops in pH reduce methane generation which causes digester souring

- pH should be between 6.8-7.2

- High pH is usually self-correcting but can cause Ammonia buildup

- pH adjustments should be made only after consulting Aquafix: 888-757-9577

Certain anaerobic digester issues may affect dosage

Contact Aquafix for specific dosage instructions

888-757-9577 technicalservice@teamaquafix.com

Alkalinity prevents fluctuations of pH in an anaerobic digester. To ensure stability of pH, it is important to monitor the relationship between alkalinity and volatile acids. A volatile acid to alkalinity ratio (VA/Alk) is an effective way to monitor digester stability. A digester should have a VA/Alk ratio of 0.34 or lower (ideally below 0.1). When this ratio gets above 0.5, pH becomes unstable Schnaars 1). VA/Alk Ratio is a much better indicator of digester upset than pH, because generally if the pH of a digester starts to drop, it is too late to easily fix the problem. With this in mind, optimal pH in a digester is between 7.0-7.2 (6.8-7 is still good), because the largest variety of methane generating bacteria can function in this range. Some methane formers can function all the way to pH 6.1 (Gerardi 101). A drop in pH is a clear indicator of anaerobic digester issues. Methane-forming bacteria break down less volatile acids outside of the optimal pH range. This again leads to an even greater buildup in volatile acids. A high pH (7.2-8) can cause NH4+ ions to turn into NH3 (ammonia). NH3 is mildly toxic to digesters (above 50 ppm), but this problem is generally self-correcting. This is because methane-forming bacteria can’t function well in high pH values and can cause a buildup of volatile acids which lower the pH back to optimal levels. If pH gets too low or too high, it is important to correct it quickly after consulting Aquafix at 888-757-9577. Lime can be used to bring pH up to 6.4 (Note: lime is difficult to get into solution and over feeding use can cause maintenance problems and safety hazards). Excess lime feeding can cause a buildup of solids which reduce digester volume (Gererdi 102). Aquafix offers a product called Boost N Lock which helps to raise and lock in pH. Once pH of 6.4 is reached, pH should be restored by a HCO3– (bicarbonate) salt. Sodium bicarbonate and potassium bicarbonate are the most commonly used salts. It is important to use a diverse group of bicarbonates because excess sodium or potassium can be toxic. Potassium and sodium become inhibitory at 200-400 ppm and 100-200 ppm respectively (Mignone 10). Addition of alkalinity should be done after consultation (888-757-9577) because too much can result in digester foaming. If the digester’s pH is too high, addition of Acetic acid can correct it fairly easily. Acid to alkalinity can be calculated by dividing total acid by total alkalinity in a sample. Total Alkalinity is measured by how much H2SO4 it takes to bring a sludge sample from pH 7 to pH 4. Total acid is measured by how much NaOH it takes to bring the sample from pH 4 to 7 again. This procedure can be seen in detail here: http://www.vtwaterquality.org/ww/om/LabManual/VolatileAcidsAlkalinity.pdf

II. Nutritional Requirements

| Nutrient | Pounds per 1000 pounds COD |

| Nitrogen | 120 |

| Phosphorous | 20 |

| Iron | 2 |

| Cobalt | .1 |

| Nickel | 0.01 |

Table represents pg. 96 in Microbiology of Anaerobic Digester (Gerardi) (converted to pounds). Care should be taken when adding micronutrients, because toxicity occurs in a digester at low concentrations. Other minerals (Mo, W, Se, Ba, Mn, and Cu) may be beneficial in very low concentrations, but additives for these minerals tend to be unnecessary. In order to function optimally, a variety of nutrients are required for anaerobic digesters. These nutrients are generally broken in categories of macro and micro nutrients. The primary macronutrients needed by bacteria are nitrogen and phosphorus. These two nutrients are required for protein production in cells. Sludge content should consist of around 12% Nitrogen and 2% Phosphorous (% of COD) (Gerardi 98). The main micronutrients required in an anaerobic digester are cobalt, nickel, and iron. These metals are necessary as biocatalyst activators for methane-forming bacteria. The minimum requirements for cobalt and nickel are 0.01% and 0.001% of COD respectively. Iron should have a minimum concentration of 0.2% of COD (Gerardi 96). Aquafix’s BioGas1 provide helpful amounts of these metals, as long as it’s added at recommended levels. Other metals such as molybdenum, tungsten, selenium, copper and barium may be of some use, but their use currently lacks any scientific verification of helping or hurting anaerobic digester issues. The other significant micronutrient required is sulfide. This is almost always present in sludge in much larger than required concentrations. A lot of digesters have problems with too much sulfur, so ferric chloride is used to precipitate some of the excess sulfur.

III. Toxicity

| Chemicals | Toxicity (ppm) |

| Ammonium (NH4+) | 1500+ |

| Ammonia (NH3) | 50+ |

| Sulfide (S-2) | 50+ |

| Nickel | 1+ |

| Iron | 5+ |

Toxicity is a common issue in methane digesters with mixed waste. Since inconsistent waste enters the digester, it is impossible to predict exactly which sorts of toxins could show up and upset one’s digester. There are, however a number of toxins that commonly cause problems in digesters. Ammonia is generally abundant in high concentrations in anaerobic digesters. At recommended operating pH levels, ammonia remains a soluble NH4+ ion. This ammonium ion is only inhibitory by around 1500 ppm. Problems arise when the pH gets over 7.2, and high concentrations of ammonium are present. This causes a buildup of soluble and sometimes insoluble ammonia. Ammonia (NH3) becomes toxic at 50 ppm. It is important to maintain some Ammonium, because 50-200 ppm NH4+ is beneficial as a source of nitrogen (Gerardi 107). If ammonia is present in high concentrations it can partially turn to ammonia gas which is dangerous to wastewater operators. Metals in too high of amounts can be a source of toxicity. Typical toxic metals include arsenic, cadmium, chromium (hexavalent), copper, nickel, zinc, and iron. Interestingly copper, nickel, zinc and iron are all beneficial nutrients in low concentrations so it is important to closely monitor conditions to see if metal toxicity is possible. Nickel becomes toxic at 1-2 ppm, copper and zinc start to become toxic from 0.5-1 ppm (Mignone 9). Iron becomes toxic at 5 ppm. Iron is unlikely to become toxic because it reacts with sulfide in digesters. The iron is beneficial because it reduces the potential of a buildup of H2S which is toxic when dissolved in digesters and a danger for operators. The only true method for removing toxicity from the system is to waste sludge from the digester. After operators do that, we recommend they use BioGas1 as their source for trace metals, so that they can carefully control the amount of each element being introduced into the digester.

Bacterial Acclimation:

If you are working in a plant which typically deals with waste that contains certain specific toxins, it is possible to improve methane generating bacteria’s resistance to them. This can be done by long term exposure to small, gradually increasing levels of toxins. Bacteria can perform well in much higher concentrations of toxins than are typically associated with toxicity if acclimated. Bacteria can become acclimated to most substances. The main exceptions are chemical cleaners and sometimes antibiotics.

IV. Operating Conditions:

- Mixing is essential to optimal digester function but over mixing causes foaming

- Solids retention time should be 20+ days

- Hydraulic retention time should be around 12 days

- No more than 450lbs of VA/1000 ft3 should be loaded

- Bacteria such as Nocardia and Microthrix can generate filaments which stabilize foaming

- Boost N Lock: pH drops have many causes; restoring pH is the first step in fixing a poorly-performing digester.

- Qwik-Zyme L: Fatty acid and FOG build-up results in foam and operational issues that eventually cause pH to drop.

- Anaerobic Food Supplement: Methanogens can struggle to keep up with incoming waste, resulting in foaming and excess acid production.

- BioGas1: Poor gas production is often caused by a trace metals deficiency.

In anaerobic digesters, most common problems can be avoided by proper mechanical equipment and maintenance. A consistent process for mixing, retention times, and feed rates can significantly help digester function. Mixing an anaerobic digester can lead to many significant benefits. Proper mixing can help avoid localized high or low temperature pockets, or localized buildup of nutrients and toxins. This enables balanced function throughout a digester, and prevents toxins for accumulating above toxic values in spots. The problem with mixing is that it is difficult to mix a digester well enough to maintain optimal function, while not over mixing. Over mixing can lead to reduction of solution surface tension and an inversion of digester contents (solids accumulating over liquids). Both of these problems can lead to foaming in a digester, or make a foaming situation worse. Many digesters incorporate intermittent mixing to avoid this problem, but that can reduce digester function. Ultimately, slightly hindered digester function is better than excessive foam buildup. Monitoring and trial and error can help determine how much mixing is ideal. When experimenting with increased mixing, it is important to make sure to stop if foam is beginning to build up significantly.

Retention times vary based on the solids contents in sludge being treated. Typically around 20 days is sufficient retention time for a mesophilic digester. Thermophilic digesters can potentially digest solids in 8 hours or less (Gerardi 154). Basically there is nothing wrong with long retention of solids, other than digestion speed will slow once the volatile solids content in the digester is low. Complete mixed anaerobic digesters have the same retention time for solids (SRT) and liquids (HRT). Some other types of digesters can recirculate the liquids and separate them from the solids. Liquids require less digestion time than solids due to lack of nutrients, but having too fast a HRT can lead to a washout of alkalinity and potentially methane-forming bacteria. Flow rate refers to the rate at which undigested sludge is entering and leaving a digester. A high flow rate can cause foaming because of inversion of solid and liquid in a solution causing solids to be on top of liquids. A maximum digested loading rate is around 450lbs of VA/1000 ft3 per day. Typically digesters operate lower than that to avoid foaming (30-50 lbs. of VA/1000ft3per day). If foaming is a problem the easiest short term fix is to reduce flow and mixing speeds and then look into long term solutions. Both these solutions could limit the productivity of a digester, but will help to avoid a substantial mess.

Loss of active capacity in a digester:

Digesters lose their active capacity with extended use. Digesters that haven’t been serviced on a regular schedule will have accumulated grit and struvite crystals. Also digesters that have difficulty with mixing and heating may accumulate two to three feet of grease and trapped solids. This may result in a 20 percent reduction of actual digester capacity. The loss of capacity can gradually decrease digester function. It should be noted that cleaning digesters is a task that should be carried out by skilled professionals. Do not leave this task in the hands of inexperienced workers.

Spotting an upset early:

The main key to spotting a digester upset is to consistently monitor alkalinity and biogas production. As long is alkalinity is maintaining around a ratio of 0.34VA:1 Alk, or better and biogas production is around 65-70% Methane and 30-35% CO2, then it is likely any digester will continue to function well.

V. Conclusion

Environmental conditions, nutritional conditions, low levels of toxicity and effective conditions of operation, are the keys to maintain a healthy digester. As long as an anaerobic digester is properly monitored and maintained, it should almost always function effectively, and when something does go wrong it will be much easier to identify the problem. When a digester is working well, it is important to document all the operating conditions so they can be replicated later. If you are experiencing any anaerobic digester issues as described in this article or if you have any questions, contact us and we’ll be happy to help.

Related to Anaerobic Digester Issues & Troubleshooting: Anaerobic Digester Foaming

If you have any other questions, call us at 888-757-9577, email technicalservice@teamaquafix.com, or contact us.

Primary Sources

Gerardi, Michael H. The Microbiology of Anaerobic Digesters. Hoboken: WILEY-INTERSCIENCE, 2003. Contains a comprehensive description of

bacteria, operating conditions, and types of anaerobic digesters.

Schnaars, Ken. What Every Operator Should Know about Anaerobic Digesters. Nashville: Operator Essentials, 2012. Contains an overview of

recommended digester environments.

Mignone, Nicholas A. BIOLOGICAL INHIBITION/TOXICITY CONTROL IN MUNICIPAL ANAEROBIC DIGESTION FACILITIES. 2005. Contains a

comprehensive list of toxicities of various compounds and abilities of bacteria to acclimate to toxins.

Glass, Jennifer B and Orphan, Victoria J. Trace Metal Requirements for Microbial Biocatalysts Involved in the Production and Consumption of Methane

and Nitrous Oxide. Frontiers in Microbiology, 2012. Contains a study trace metal requirements in anaerobic digesters for methanogenesis.

Secondary Sources

Chen, Ye, Cheng, Jay J and Creamer, Kurt S. Inhibition of Anaerobic Digestion: A Review. Science Direct 2005. A study of the effects of inhibitors on

digester production.

Ersahin, Mustafa Evren, and Hale Ozgun. Anaerobic Treatment of Industrial Effluents: An Overview of Applications. Comp. Kaan Dereli and Izzet

Ozturk. Istanbul: INTECH, 2011. Contains an overview of the various types of anaerobic digesters used in industry and wastewater treatment.

Kim, M., Ahn, Y.-H., & Speece, R.E. (2002). Comparative process stability and efficiency of anaerobic digestion; mesophilic vs. thermophilic. Water Research, 36, 4369-4385.

Labatut, R. A., Angenent, L. T., & Scott, N. R. (2014). Conventional mesophilic vs. thermophilic anaerobic digestion: A trade-off between performance and stability? Water Research, 53, 249-258.