Wastewater Food Supplement Comparison Study

by Justin Hall of UW-Steven’s Point.

Summary

The Wisconsin Institute for Sustainable Technology (WIST) is a department within the College of Natural Resources at the University of Wisconsin – Stevens Point Campus, located in Stevens Point, Wisconsin. The Wisconsin Institute for Sustainable Technology provides research, laboratory services and education for businesses and industries. Through our contract research, we work with companies such as Aquafix to bring new ideas and innovation to their respective industries.

Drawing off the success of the first round of experiments, Aquafix reached out to the Wisconsin Institute for Sustainable Technology (WIST) for additional trials. Initially, Aquafix approached WIST to evaluate their product SmartBOD and its effectiveness as a source of carbon for wastewater treatment facilities. Aquafix wanted an independent third-party evaluation of SmartBOD. These sources of carbon are beneficial when wastewater plants have issues with low F:M ratios, need recovery from upset, or want to lower effluent nutrient levels.

After making updates in its formula, Aquafix wished to test their new product for its effectiveness as a source of carbon for wastewater treatment versus a glycerin-based carbon source.

Experimental Design

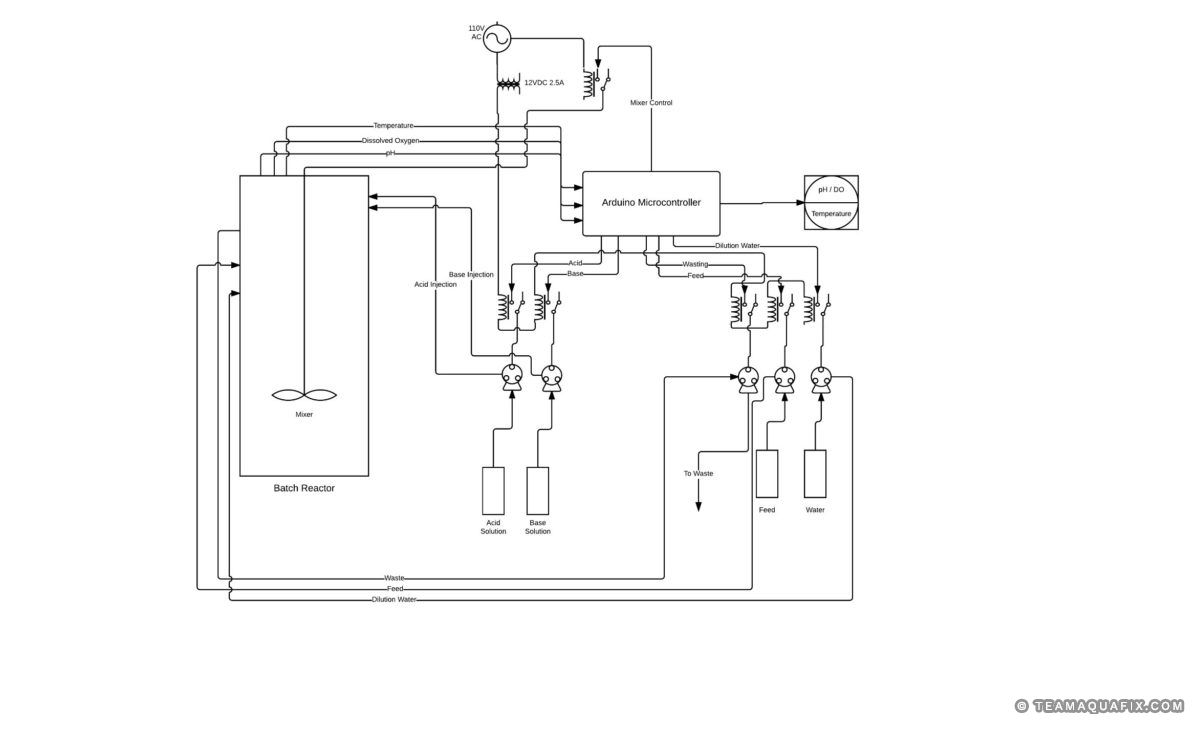

We made use of two batch reactors from the previous study. Constructed out of 6” PVC pipe the reactors have a total volume of 7L and a working volume of 5L. The reactors have microcontrollers, controlling dissolved oxygen, pH and monitoring temperature. These microcontrollers also control feed pumps, wasting pumps, dilution pumps, and overhead mixing. WIST staff designed a custom, touchscreen interface to control and monitor the reactors. Shown in Figure 1 is a design schematic of the reactors.

Figure 1: Design schematic for batch reactors

Experimental Conditions

Reactors have a source of carbon added to them as a food for the microorganisms responsible for the treatment of the wastewater. The experiment sought to test the effectiveness of Aquafix’s SmartBOD to a glycerin-based carbon source.

Reactors have controls for monitoring pH, dissolved oxygen and temperature. The reactor control interface allowed for setting control limits for pH and dissolved oxygen. The use of acid/base addition and an air pump allowed the reactors control interface to keep these values within limit. The reactors have no control for temperature, only monitoring. A SD card interface logs all pH, dissolved oxygen, and temperature readings.

We set the conditions for the experiment after discussions with Aquafix.

Table 1: Experimental conditions in batch reactors

Parameter

Setpoint

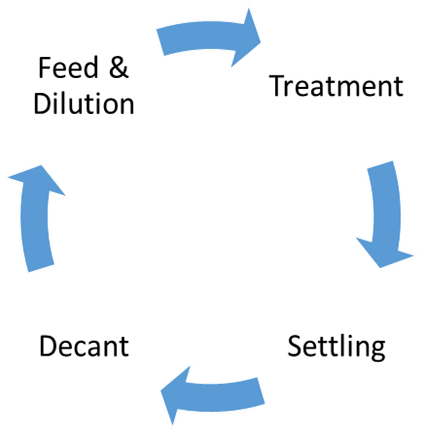

Reactors complete three cycles daily, with each cycle lasting eight hours. Figure 2 below details cycle steps.

Figure 2: Reactor cycle

Test Methods

Testing occurred for the following analytes; ammonium, soluble reactive phosphorus, chemical oxygen demand, mixed liquor suspended solids, effluent suspended solids, and sludge volume index. Table 2 lists the standard test method used.

Table 2: List of standard methods

Test

Method

Results & Discussion

Ammonium and Soluble Reactive Phosphorus

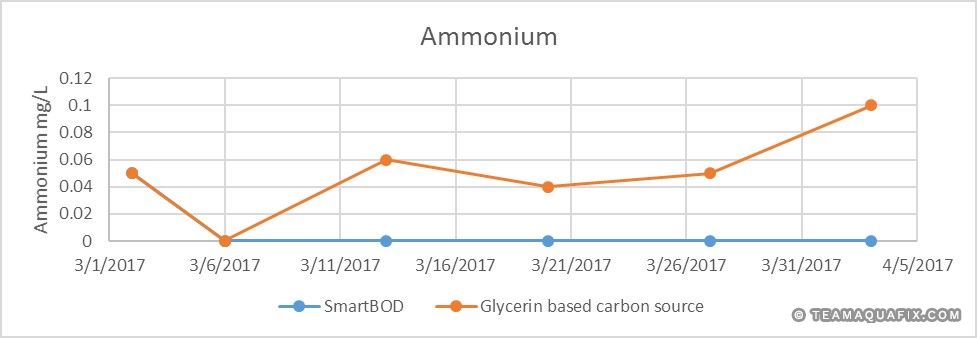

Ammonium and soluble reactive phosphorus are two nutrients measured by wastewater treatment plants. Analysis for these nutrients occurred on reactor effluents. The glycerin-based carbon source reactor presented with low but detectable levels of ammonium, with none present (except for initial) in the SmartBOD reactor (Table 3, Figure 3).

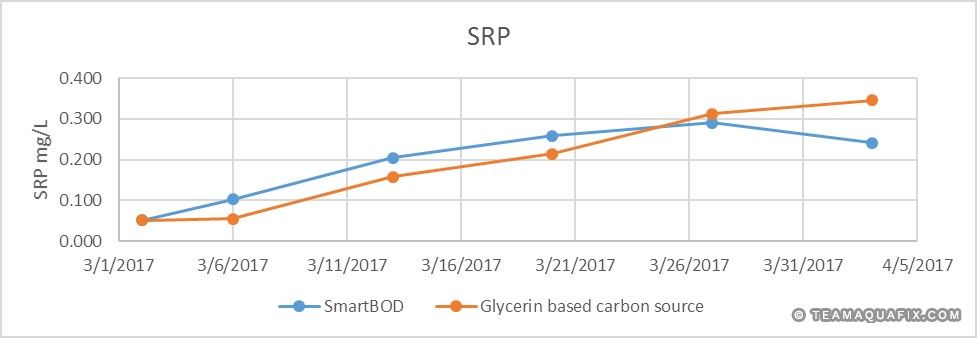

Phosphorus, measured as SRP presented in both reactors (Table 4, Figure 4). Concentrations in both reactors increased during the study. The reactor with the glycerin-based carbon source had the highest final concentration of SRP.

Table 3: Ammonium concentrations in reactor effluent

Date

mg/L NH3-N

SmartBOD

mg/L NH3-N

Glycerine Based Carbon Source

mg/L NH3-N

Figure 3: Ammonium concentrations in reactor effluent

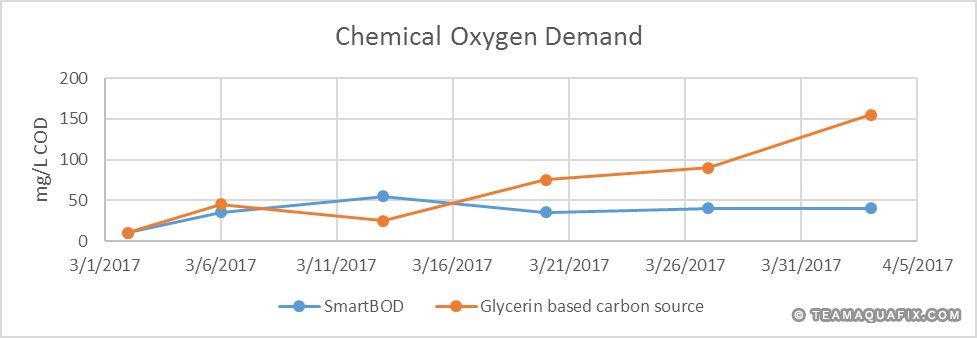

Chemical Oxygen Demand

Chemical oxygen demand (COD) in reactor effluent is an indicator to the effectiveness of the wastewater treatment process. WIST staff tested COD in reactor effluent, with results listed in Table 4 and Figure 5. Levels of COD in reactor effluents were similar at the start of the experiment. However, levels of COD in the reactor using the glycerin-based carbon source increased during the second half of the experiment. This increase would indicate that the ability of the MLSS ability to treat the wastewater is decreasing. Levels of COD in effluent from reactor using SmartBOD remained constant. This stable, continual removal of COD indicates that the MLSS is effective in its treatment.

Date

mg/L PO43-

SmartBOD

mg/L PO43-

Glycerine Based Carbon Source

mg/L PO43-

Figure 4: SRP concentrations in reactor effluent

Chemical Oxygen Demand

Chemical oxygen demand (COD) in reactor effluent is an indicator to the effectiveness of the wastewater treatment process. WIST staff tested COD in reactor effluent, with results listed in Table 4 and Figure 5. Levels of COD in reactor effluents were similar at the start of the experiment. However, levels of COD in the reactor using the glycerin-based carbon source increased during the second half of the experiment. This increase would indicate that the ability of the MLSS ability to treat the wastewater is decreasing. Levels of COD in effluent from reactor using SmartBOD remained constant. This stable, continual removal of COD indicates that the MLSS is effective in its treatment.

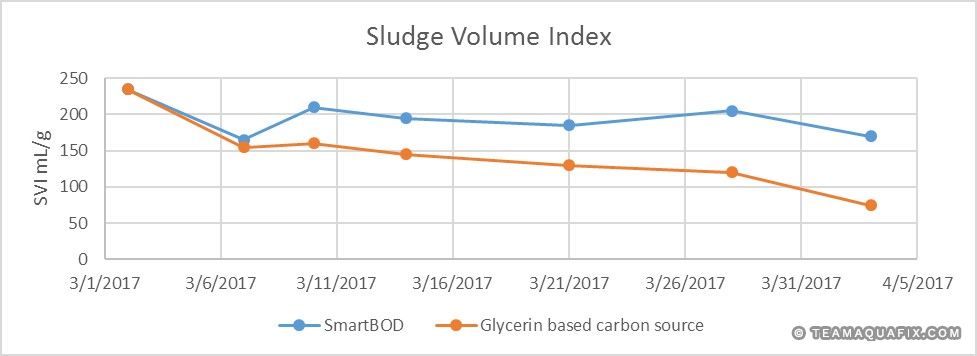

Sludge Volume Index

Sludge volume index (SVI) is an additional metric used to quantify the health of MLSS. SVI is the volume of solids occupied after a 30-minute settling period. This test describes the ability of the MLSS to settle and compact. SVI values tend to differ from treatment process to treatment process. There are general guidelines published and are reported in Table 6.

Date

mg/L COD

SmartBOD

mg/L COD

Glycerine Based Carbon Source

mg/L COD

Figure 5: Values for chemical oxygen demand in reactor effluent

”SVI

Sludge Characteristics

The initial sludge volume index on the wastewater had a value of 235 mL/g, slightly elevated above the optimal range according to the guidelines. We do not believe that this is a cause for concern as it is only slightly above the high range of 200 mL/g for optimal sludge settling. The SVI for the SmartBOD reactor remained steady around 200 mL/g. WIST staff observed good floc formation during the test. SVI for the glycerin based carbon source trended downward during the experiment. The flocs became dense and compacted at the end of the experiment.

Table 7: Mixed liquor sludge volume index

Date

SVI mg/L

SmartBOD

SVI mg/L

Glycerine Based Carbon Source

SVI mg/L

Figure 6: Mixed liquor sludge volume index

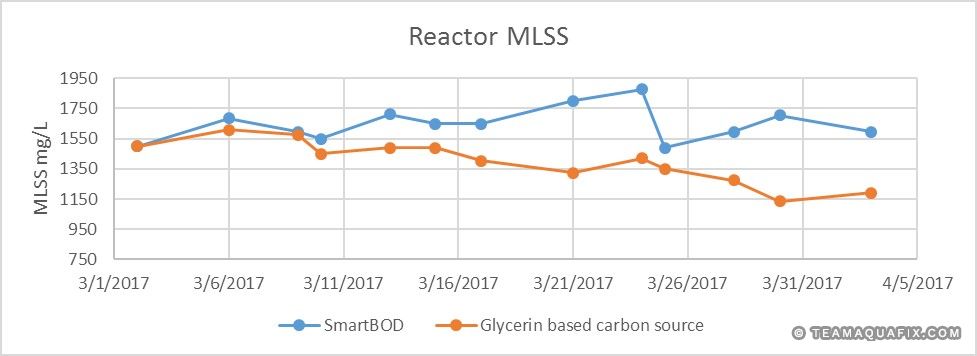

Suspended Solids

Mixed liquor suspended solids is another test to aid in quantifying the health of wastewater sludge. Testing for MLSS occurred on a regular basis. The test for MLSS is done for two reasons; first it allows WIST staff to know how much of the MLSS to waste, and secondly it gives a picture of the health of the sludge over time. Wastewater operators keep MLSS at a constant level. This requires regular wasting, or removal, of a portion of the sludge.

WIST staff took measurements of MLSS to determine wasting amounts. The target value for MLSS during this experiment was 1500 mg/L. MLSS results, listed in Table 8, were pre-wasting values. These values allowed WIST staff to calculate how much of the sludge to remove from the reactors.

Continual MLSS growth occurred from the reactor fed with SmartBOD. This indicates that the microorganisms present have enough food and nutrients to multiply. Continual removal of sludge also lowers the age of it. The reactor fed with the glycerin-based carbon source did not have the amount of MLSS growth as observed in the SmartBOD reactor. The reactor with the glycerin-based carbon source had a gradual decrease in MLSS during the study.

Table 8: MLSS before wasting

Date

Reactor MLSS mg/L

SmartBOD

Reactor MLSS mg/L

Glycerine Based Carbon Source

Reactor MLSS mg/L

Figure 7: MLSS Before Wasting

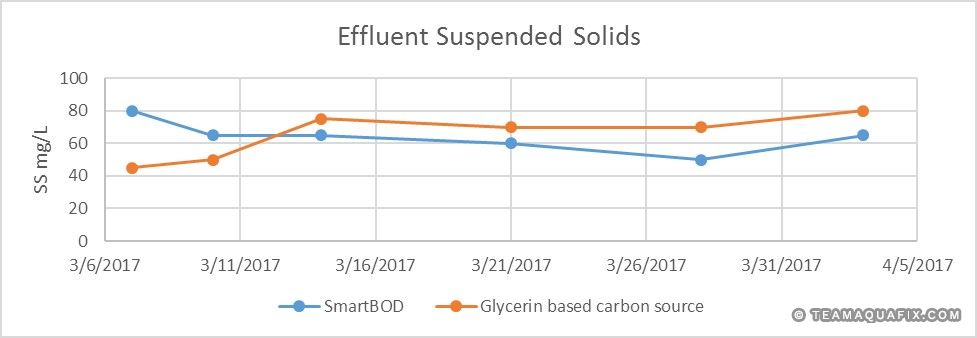

Table 9: Effluent suspended solids

Date

Effluent SS mg/L

SmartBOD

Effluent SS mg/L

Glycerine Based Carbon Source

Effluent SS mg/L

Figure 8: Effluent suspended solids

Conclusion

Addition of SmartBOD as a carbon source outperformed the glycerin-based carbon source in terms of COD removal, settling, floc formation, and ammonium removal. There wasn’t a clear advantage to phosphorus removal. The evidence from this study supports that SmartBOD is an efficient source of carbon for wastewater treatment plants as compared to the glycerin-based carbon source.